printing directly with print waste

universal pellet extruder

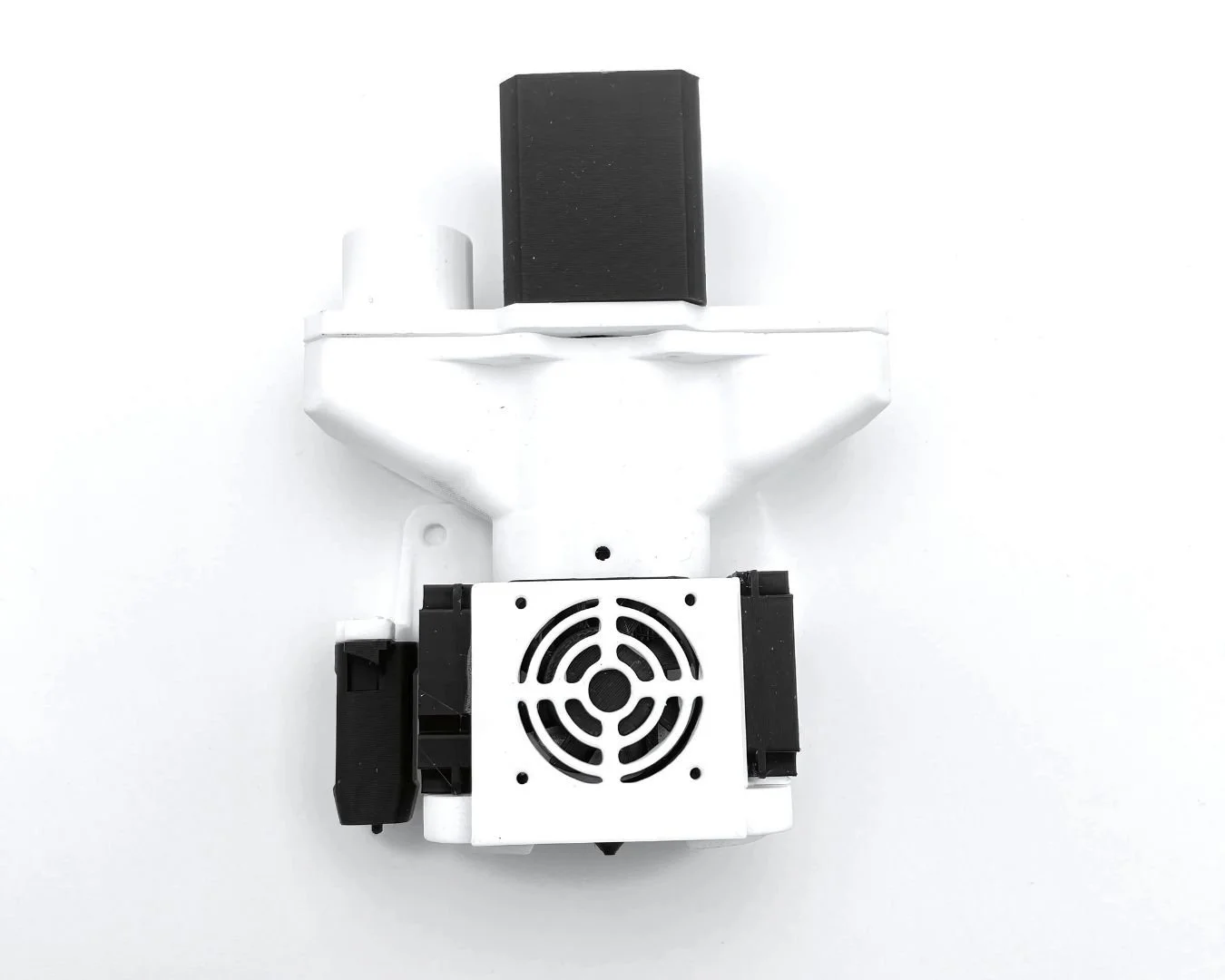

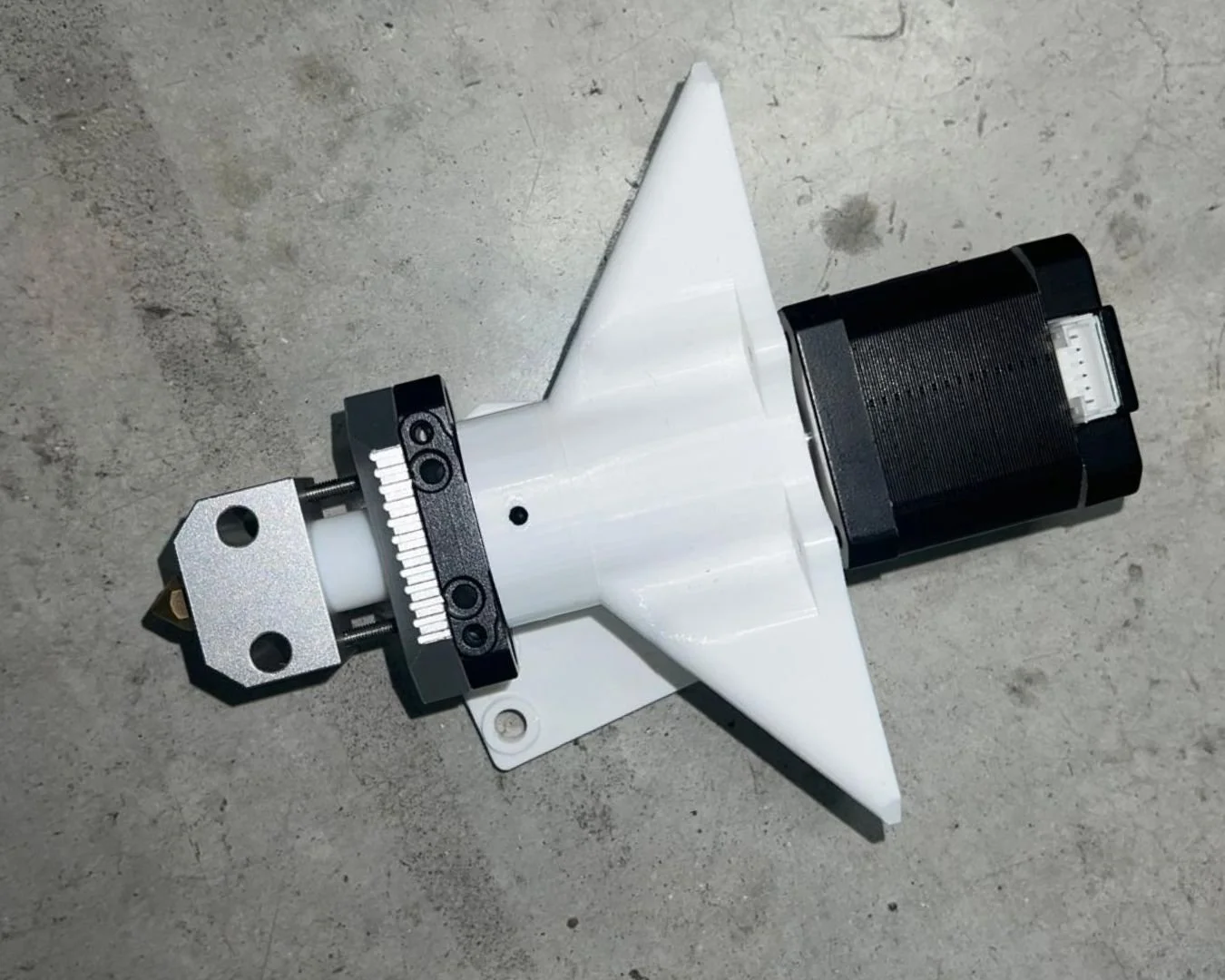

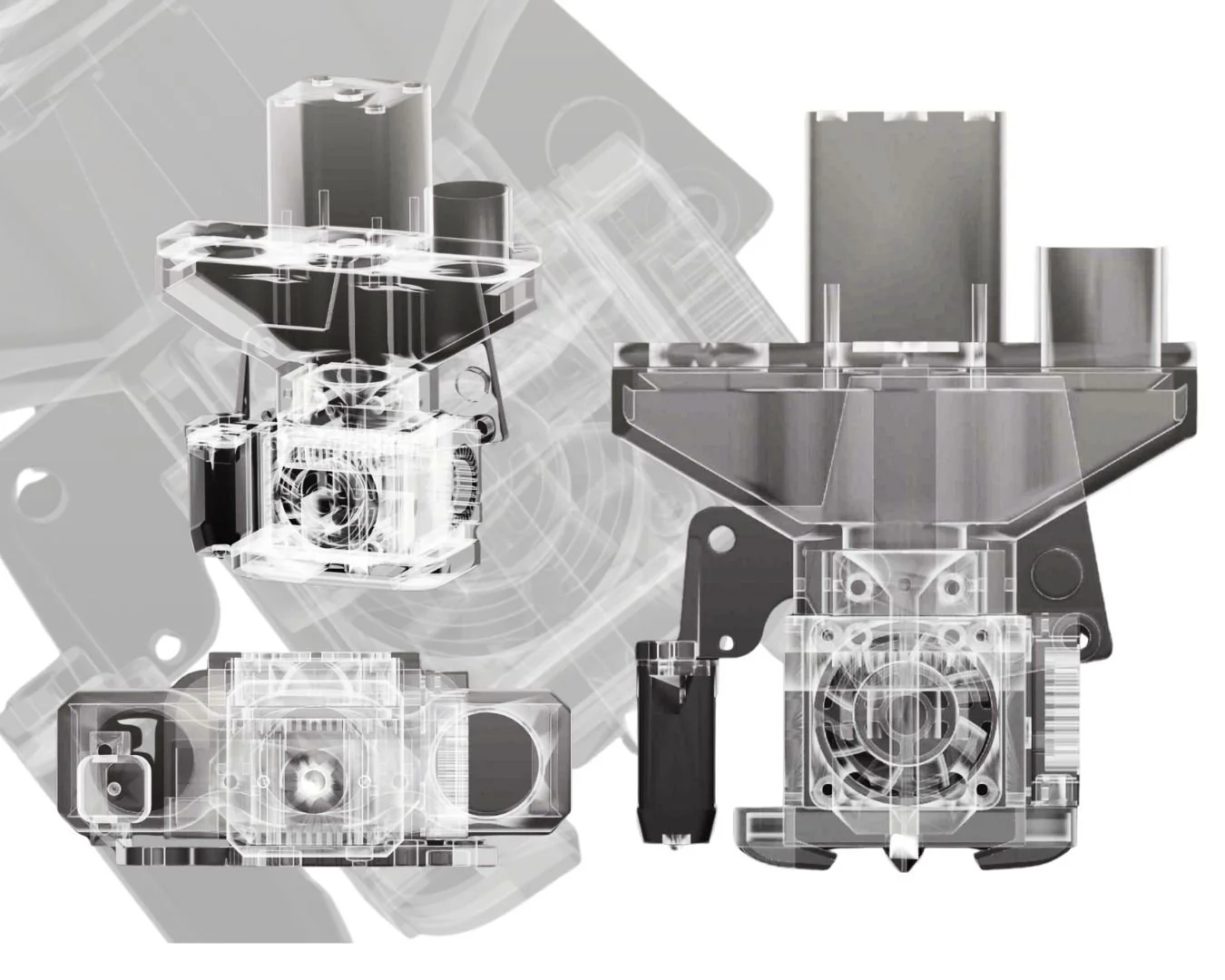

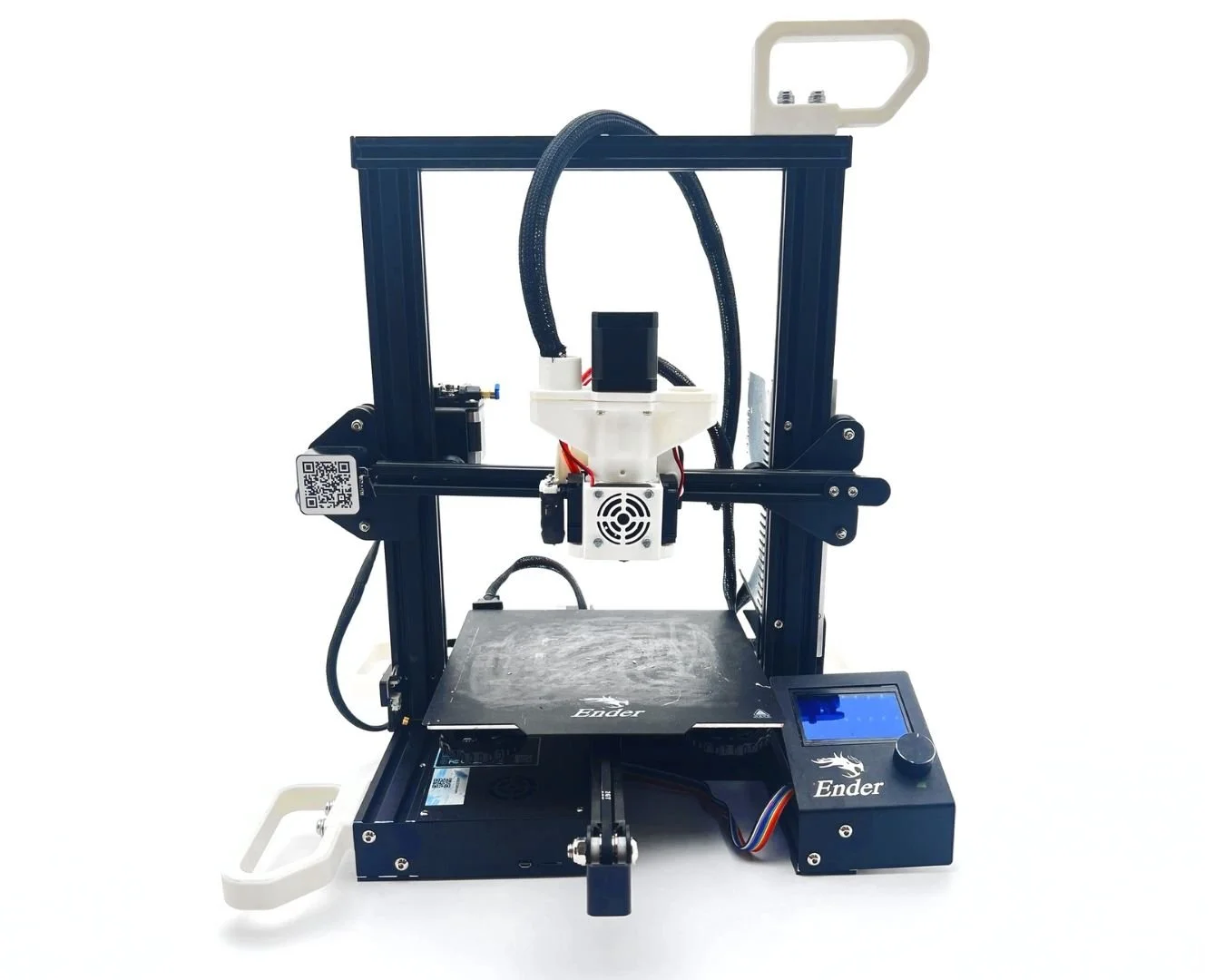

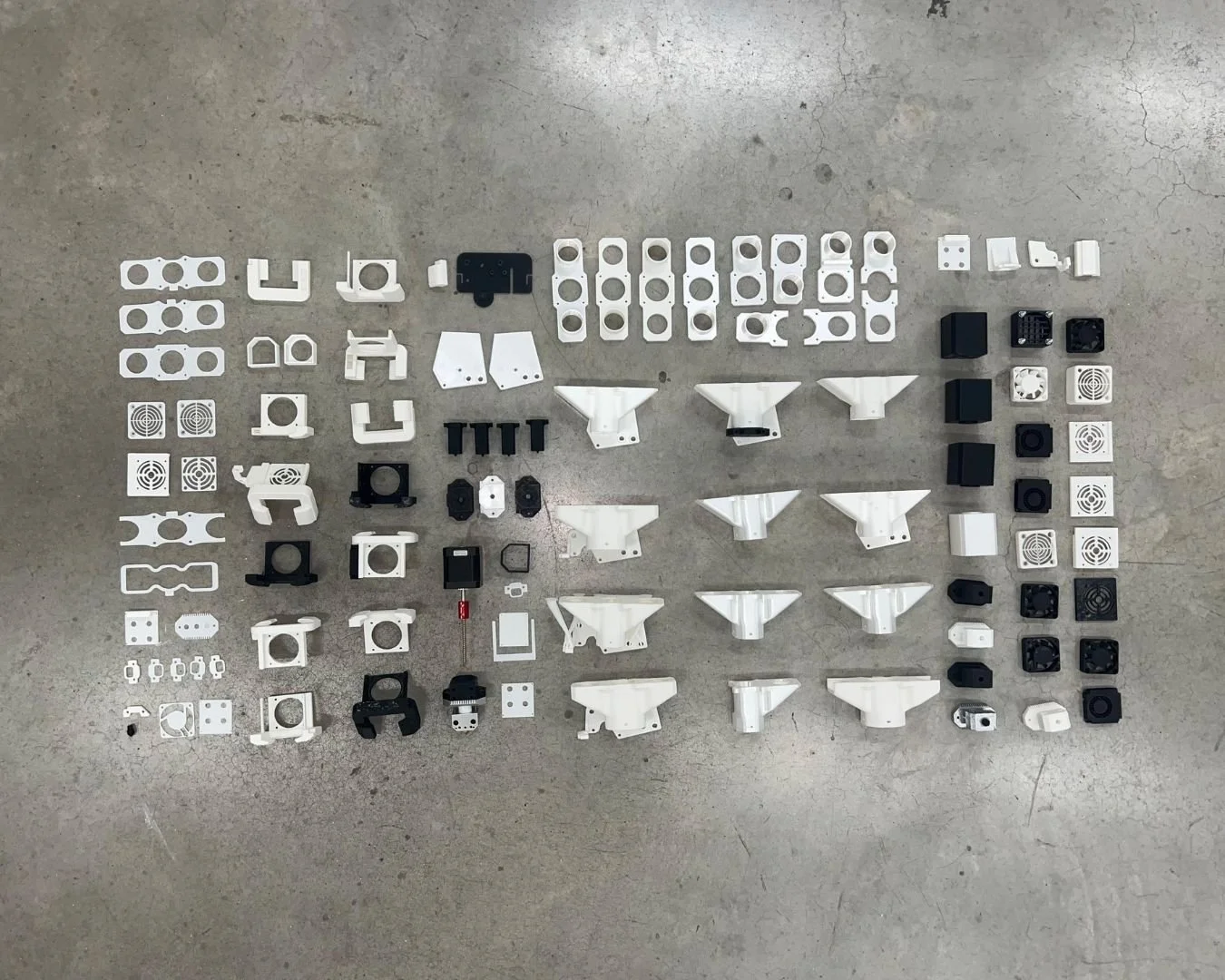

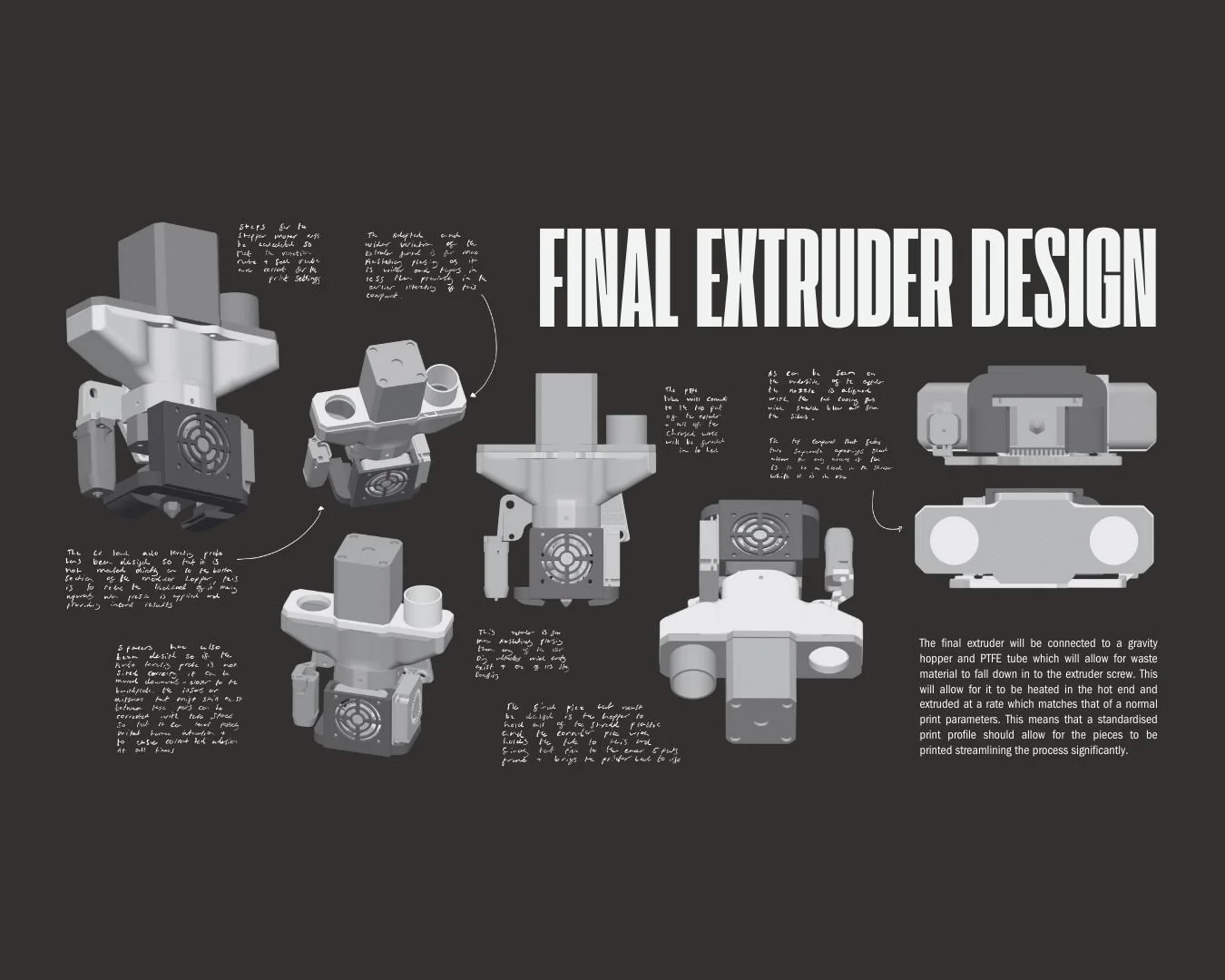

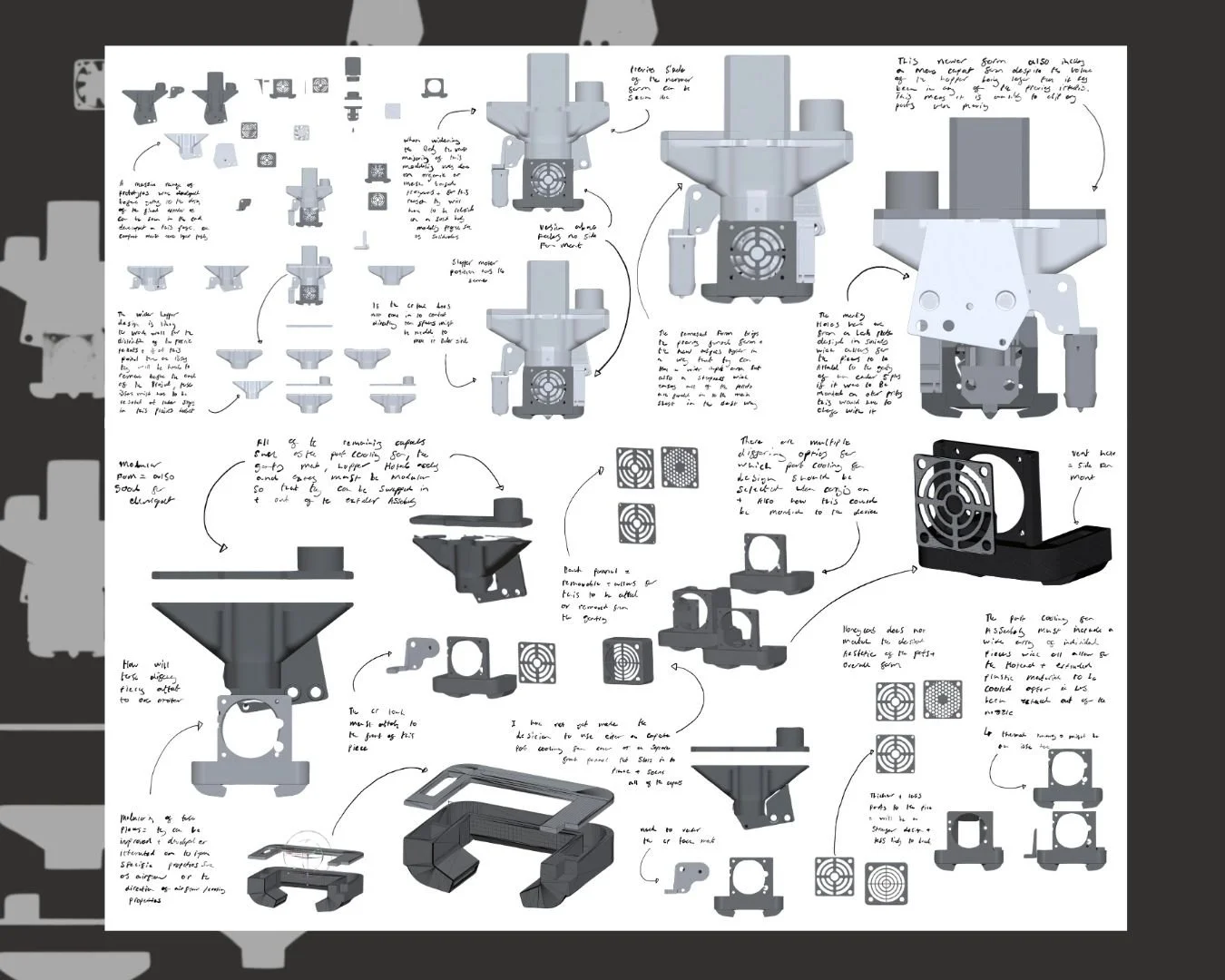

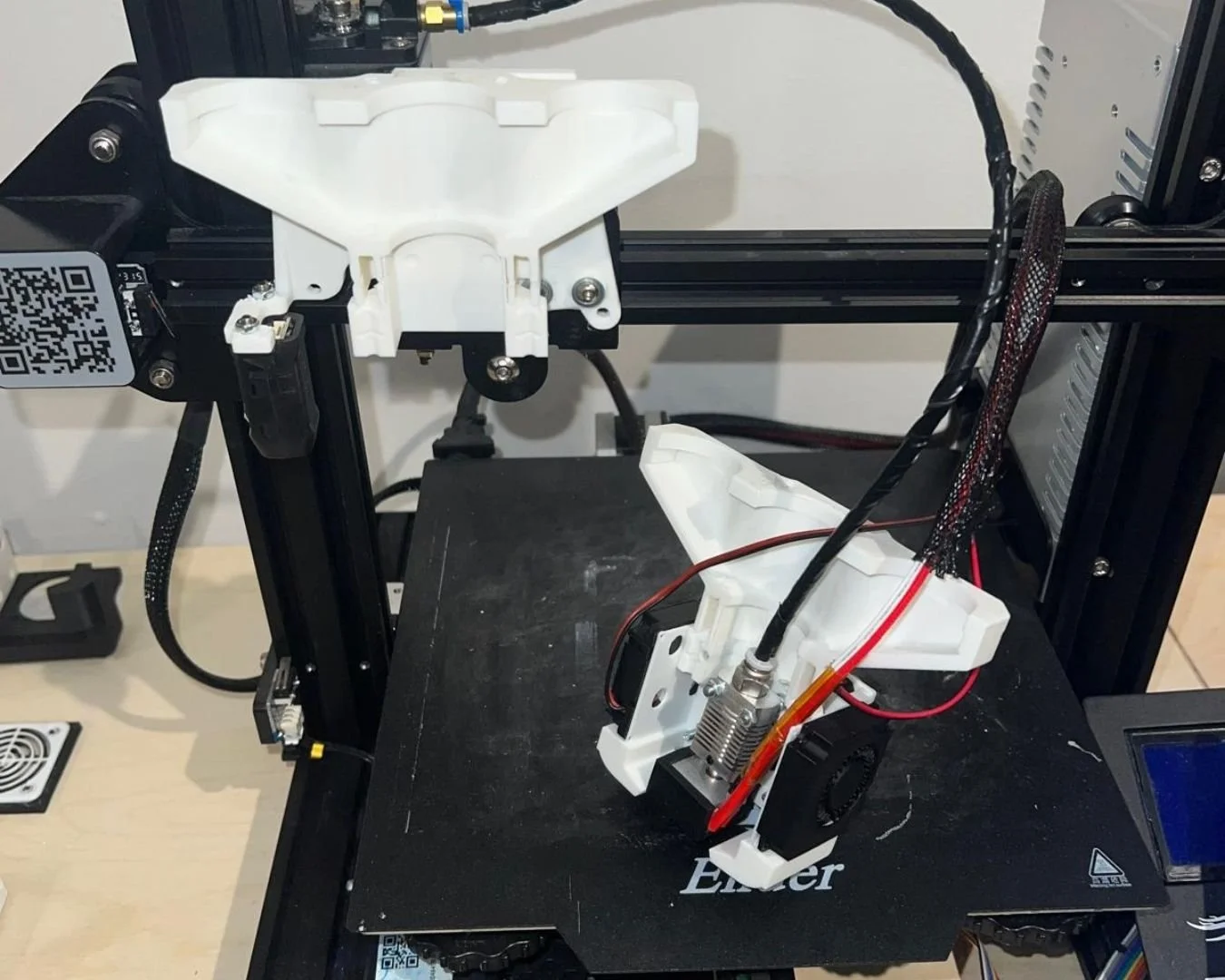

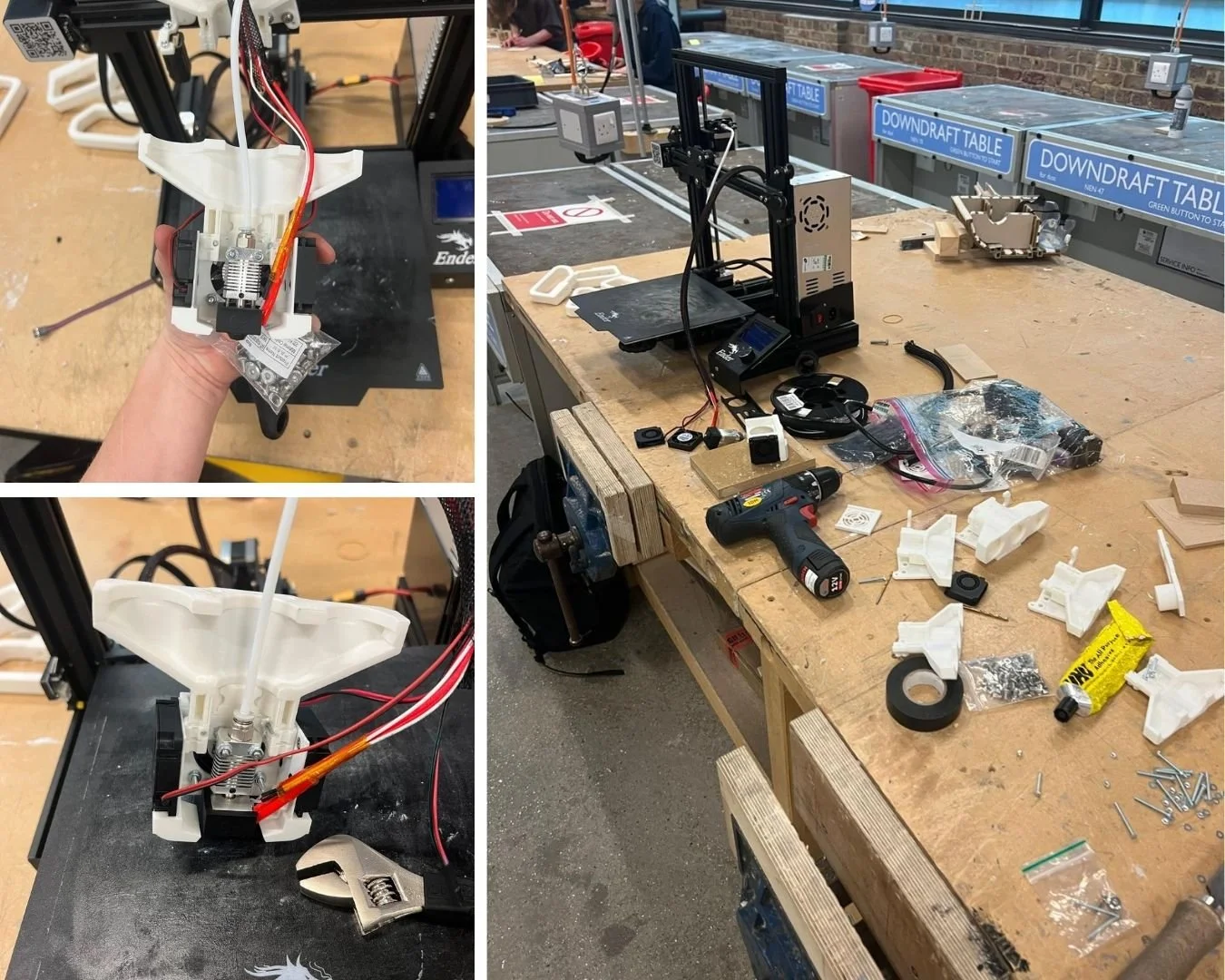

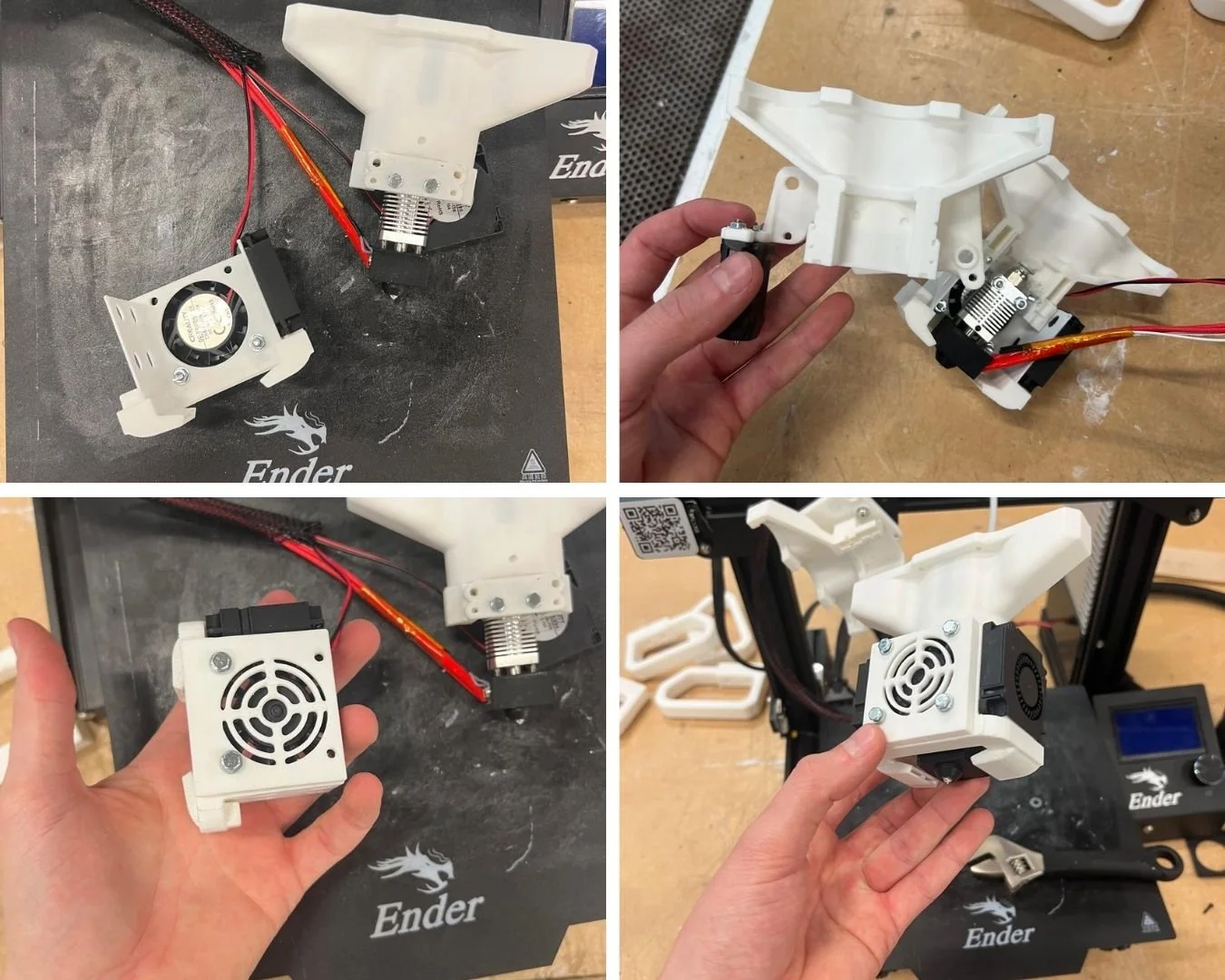

The universal pellet extruder was created as another individual component of my Master’s final project: the collaborative Industry 5.0 investigation. Built by hacking and reengineering an old 3D printer, it introduced a custom hopper, auger, and hotend assembly, enabling the machine to run on shredded waste while remaining compatible with standard slicing software. The final prototype still required further calibration for the hopper; however, the exploded views shown in the images house the standard components of a 3D printer, allowing us to run preliminary form tests and present an aesthetic prototype. This proof-of-concept model was exhibited as a working system in appearance, demonstrating the feasibility of the design. Serving as a crucial link in the ecosystem, the extruder bridged the gap between recycled fragments and new objects, extending the life of consumer machines while showing how circular processes could support creative making.